Our Technology

Our Technology

FlexiCharge is in the late stages of developing a flexible thermoelectric generator (TEG) that will act as a supplemental power supply, charging rechargeable batteries in wearable devices.

Our flexible TEGs use the difference in temperature between your skin and the air around you to generate 2 – 5 volts of power.

Production and Flexibility

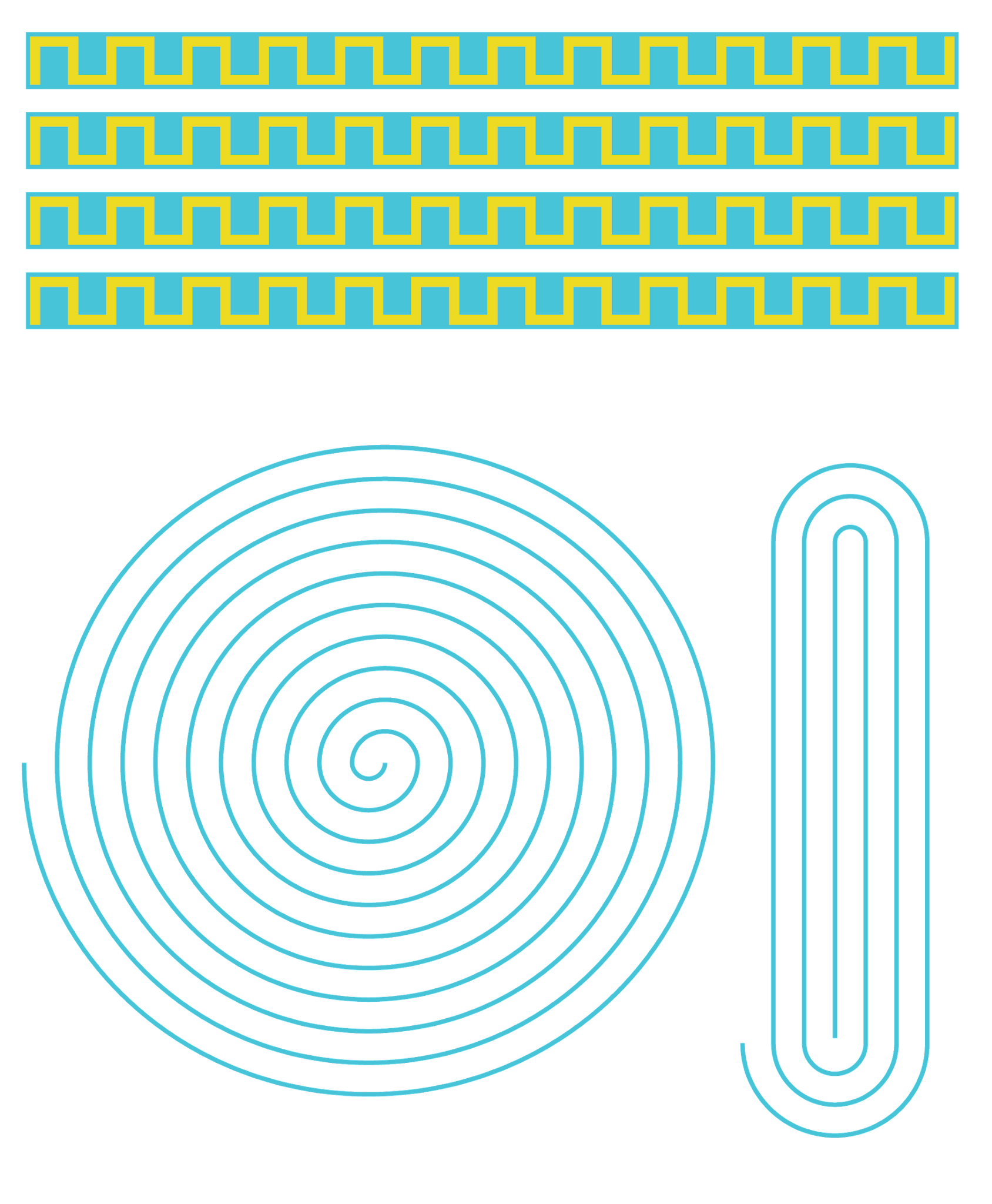

Our proprietary and cost-effective manufacturing process includes 2D printing, Low-temperature short-duration curing, and uniaxial mechanical pressing to produce flexible TEG strips represented in fig. 1 on the left.

The power and voltage of our TEGs increases as the number of TE elements increase. The spiral graphics on the left show examples of how the TEG strips could be positioned within a device.

Click To Read The Technical Papers

Temperature Strategy

Our targeted temperature difference (∆T14K) to achieve 2 – 5 volts is 25F which based on average temperature data in the United States and average human skin temperature data is well within the range needed for our device to function.

Ref: Average Temperatures by State 2024

Read Article

Ref: Regional Variation of Human Skin Surface Temperature

Join Us as a Trial Partner

Are you ready to be a part of the next big innovation in wearable tech? FlexiCharge is seeking partners to collaborate and test our cutting-edge technology.

Current vs Goal Tech Specs

Current – Lab Scale

Temp Difference (ΔT) – 40K

-

Watts – 300 μW -

Amps – 10-20 mA -

Voltage – 40mV Voc -

Power density – 5mW/cm2

With integrated step up circuit – 2-5V

Goal – Q1 2025

ΔT – 15K

-

Watts – 80 μW -

Amps – 5-10 mA -

Voltage= Voc= 40mV -

Power density – 5mW/cm2

Integrate 2mm x 2mm step up circuit – 2-5V

Charging Batteries or Capacitors

Our goal is not to replace batteries but to provide a tunable and flexible self-sustaining power source that compliments rechargeable batteries and capacitors in wearable devices.

Giving inventors and designers more opportunities than ever before to either reach unlimited uptime or decrease battery size while keeping the same uptime providing more freedom to design for usability.

Unlimited Uptime vs Design Flexibility

Two benefit pathways lay before us.

On one hand, there is a pathway to unlimited uptime. Your wearables would be fully powered, tracking data, and presenting information 24/7.

If unlimited uptime is not the goal, our flexible TEGs open up the opportunity to reduce the battery size drastically while sustaining required uptime. Increasing design flexibility allowing OEMs to focus on form and function rather than making design compromises for adequate power.